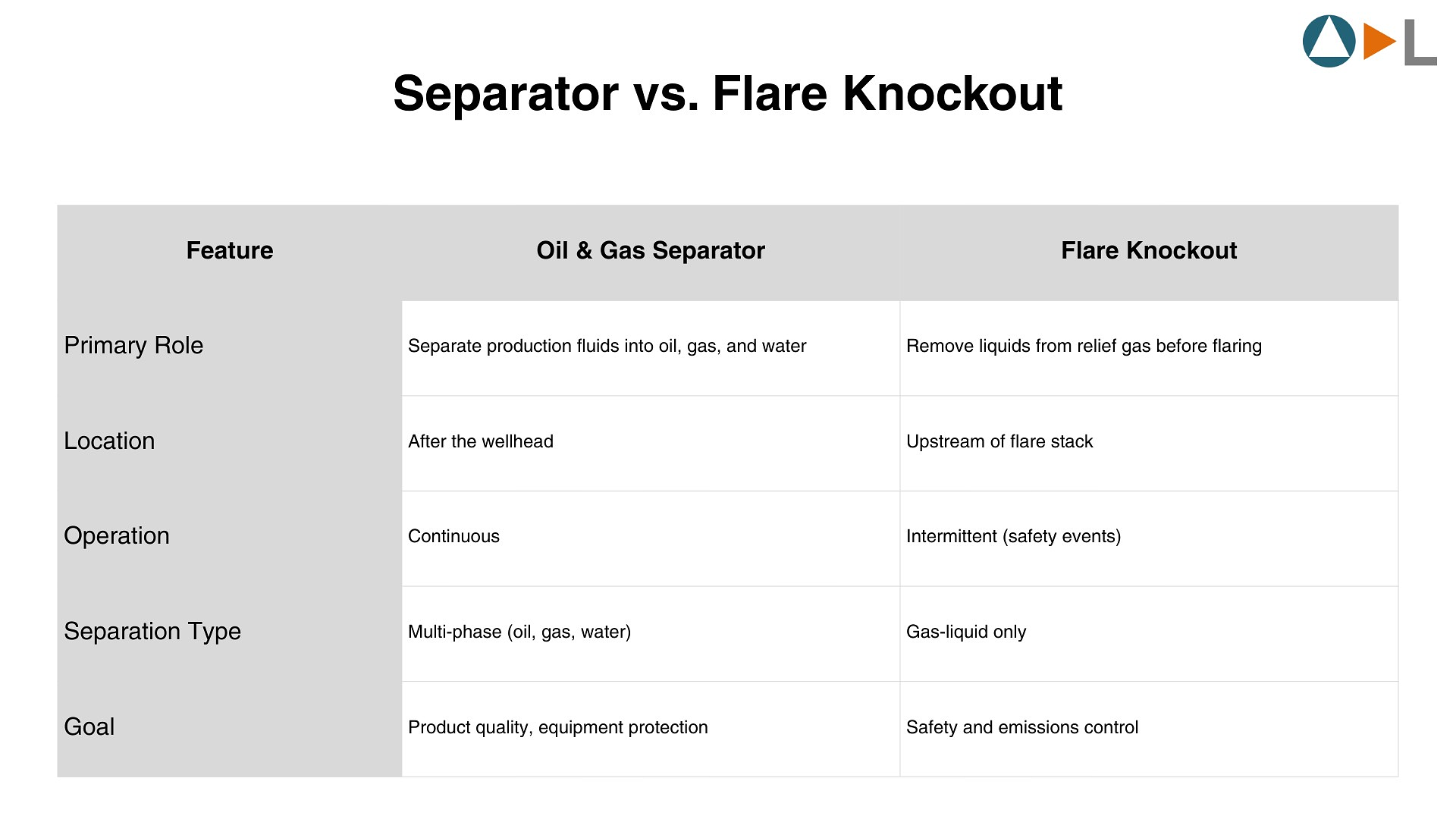

In upstream oil and gas production, not all separation equipment serves the same purpose. Two commonly confused but fundamentally different pieces of equipment are the oil and gas separator and the flare knockout drum (KOD). While both remove liquids from gases, they operate at different stages, serve different functions, and protect different parts of the system.

Processing vs. Protection

Oil and Gas Separators are installed early in the production process, immediately after the wellhead. Their job is to separate the well stream into oil, gas, and water so that each can be handled, transported, or sold efficiently. This separation is essential for protecting downstream equipment, meeting product specifications, and ensuring smooth operations.

Flare Knockout Drums are part of the safety and emissions control system. Located upstream of the flare stack, they come into play during pressure relief events, such as blowdowns, emergency shutdowns, or maintenance, when gases are vented. Their purpose is to remove liquid droplets from the gas before it is flared, preventing safety hazards like burning liquid fallout or unstable flare flames.

How They Work

Separators operate continuously, using gravity (and sometimes centrifugal force) to separate fluids by density. Gas rises, water sinks, and oil stays in between. Performance depends on factors like pressure, residence time, and flow rates.

Flare Knockouts also rely on gravity, but they work intermittently. When a surge of gas and liquid enters the vessel, a sudden drop in velocity allows liquids to settle out before the gas moves on to the flare tip.

Placement in the System

- Oil & gas separator are positioned directly after the wellhead or choke manifold.

- Flare knockout drums are located just before the flare stack, at the end of the pressure relief header.

Design and Operation

- Separators are designed for continuous, steady flow. They may be two-phase (gas/liquid), three-phase (gas, oil, water), or four-phase (gas, oil, water, sand) and sized for maximum production efficiency.

- Knockouts are sized for slug handling, managing sudden bursts of gas and liquid. They can be vertical, horizontal, or hybrid, depending on space and flow requirements.

End Use of Separated Materials

- From separators, oil is sent to storage tanks, gas to sales lines or combustion, and water to treatment or disposal.

- From knockouts, gas is routed to the flare for controlled combustion, and collected liquids are drained and disposed of safely.

Two Systems, Two Missions

Both separators and flare knockout drums are critical in oilfield operations but for different reasons. Separators start the production process by delivering clean, separated streams for transport and sale. Knockout drums ensure that emergency gas handling is safe, controlled, and environmentally responsible.

By understanding the differences, operators can better design, operate, and maintain these systems to keep production efficient and compliant with safety and environmental standards.

Shop our selection of separators and knockouts. If you have any questions, please feel free to contact us.